How illuminated letters are installed: process explained.

Creating standout illuminated signage involves a meticulous process, with each step carefully planned and executed to ensure the best possible results. Here’s an in-depth look at how illuminated letters are brought to life, from selection to final installation.

Selecting the Right Letters

Choosing the correct type of illuminated letters forms the foundation of a successful installation. Several factors are considered to ensure the signage delivers the desired impact. For instance, halo illumination works best on walls painted in vivid colors, where the light creates a soft, glowing outline around the letters.

However, on dark or black walls, this effect tends to become nearly invisible, making it less effective. In such cases, face and edge-lit letters are preferred. These types of illumination provide bright, direct light that stands out sharply against darker backgrounds, ensuring the sign remains visible and impactful regardless of the wall color.

Placing halo illuminated built ups on a wall painted in vivid colours will achieve a much brighter halo effect.

A sign installed on a black wall or painted in shades of grey will cause the light to be absorbed and limit the halo effect.

Inspecting the Site and Wall

Before any installation work begins, the site is thoroughly inspected to check for any hidden services, such as electrical wires, water pipes, or other utilities behind the wall. Detecting these elements early is critical to avoid accidental damage during installation, which could lead to costly repairs or safety hazards. The wall’s structural integrity is also assessed to ensure it can support the weight of the illuminated letters. This careful investigation sets the stage for a smooth and problem-free installation.

Marking and Drilling

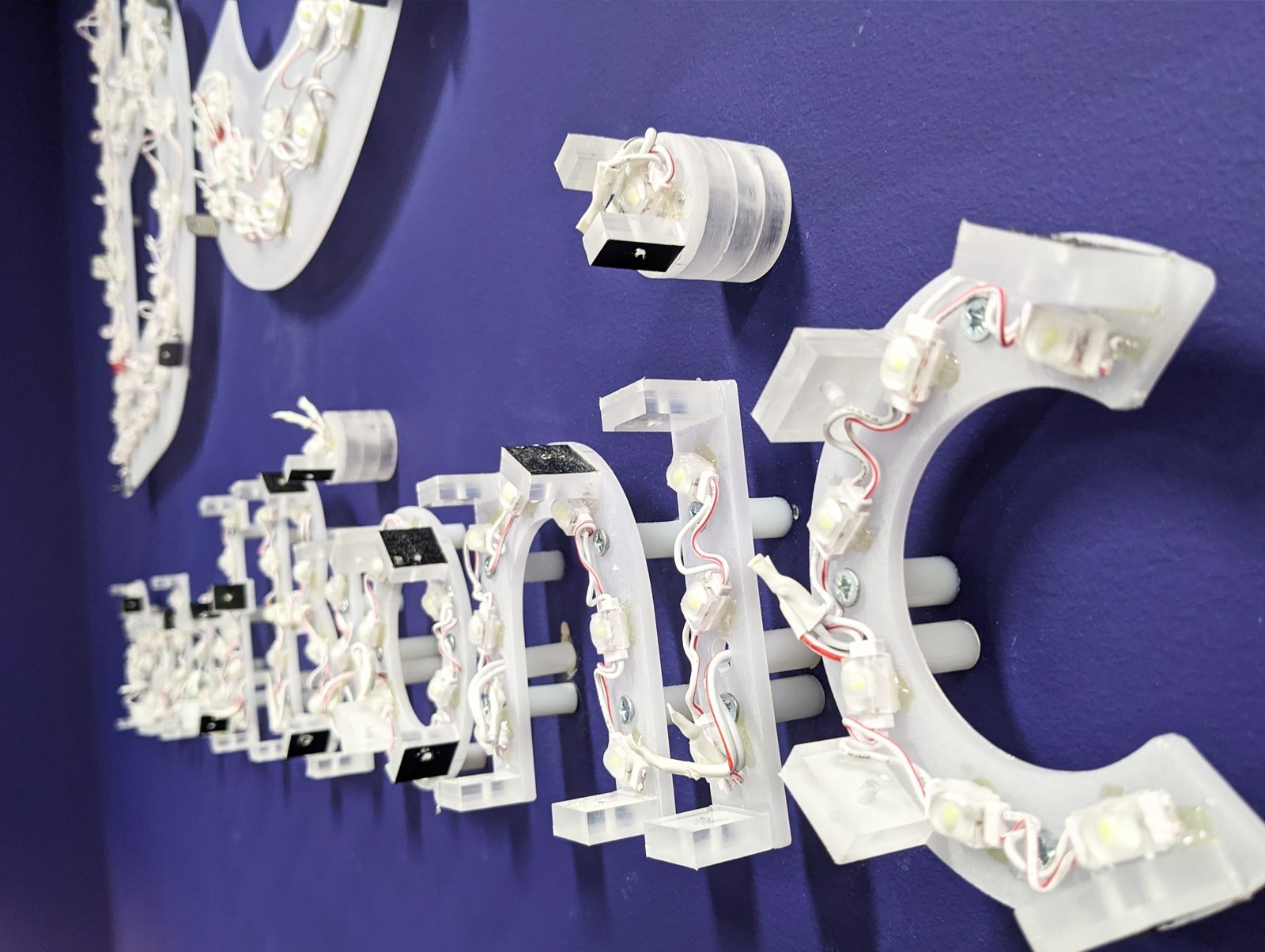

After the site inspection and identification of any potential obstacles, the next step involves marking the precise positions for the sign on the wall. A detailed template is used to ensure every letter is aligned correctly, with consistent spacing between each one. Once the layout is confirmed, holes are drilled for the stud fixings and wire feeds. This process requires precision and attention to detail, as the stability of the letters and the neatness of the wiring depend on the accuracy of these drilled holes. Proper drilling ensures the letters are securely anchored to the wall and the wiring is neatly concealed.

The wiring is being fed through the wall to be connected inside

Backtrays are mounted using stud fixings to achieve halo illumination

Cutting Access Panels

Effective wiring management is essential for both the functionality and appearance of illuminated signage. Access panels are cut at strategic locations, usually at the top or bottom of the wall, to facilitate this. These panels allow cables to be fished out and connected properly. Depending on the size and complexity of the sign, multiple access panels might be required to ensure all wiring is accessible and neatly routed. These panels are cut with precision to minimize disruption to the wall’s surface and are positioned in a way that makes them easy to cover up later, ensuring a clean, professional finish.

Depending on where the power supply is located, access panels will be cut out in the middle of the wall or near ceiling

If the power supply is located closer to the ground, the access panels can be positioned just above the floor level

Connecting and Testing

With the access panels in place and the wiring exposed, the next step involves connecting the letters. Each letter is wired together in sequence, creating a unified electrical circuit. This circuit is then connected to a transformer, which regulates the voltage and ensures consistent lighting across all letters. The transformer is connected to the nearest power source, typically through an existing electrical outlet or directly to the office lighting system, allowing the sign to operate in sync with the building’s lights. After all connections are made, the electrical system is thoroughly tested to verify that each letter lights up as expected. This testing phase is crucial to identify and resolve any issues before the installation is finalized.

Covering Access Panels

Once the wiring is confirmed to be functioning correctly, the next step involves covering the access panels. Independent plastering and painting contractors appointed by the client are engaged to expertly restore the wall to its original condition. The cut-outs are plastered over, and the surface is carefully smoothed and painted to match the surrounding wall. This attention to detail ensures there is no visible trace of the installation work, leaving the wall looking clean and undisturbed, with only the illuminated letters as the focal point.

Final Electrical Testing and Sign-Off

Before the project is fully completed, a final round of electrical testing is conducted to ensure everything is in perfect working order. This step ensures that all connections are secure, the lighting is consistent, and the sign operates safely within the building’s electrical system. An appointed electrician, typically hired by the client, carries out this final inspection. Their sign-off is essential for certifying that the installation meets all local safety and regulatory standards. This step not only ensures compliance but also provides peace of mind that the illuminated sign is both safe and reliable.

A complete set of halo illuminated letters installed by Signs Base

Face illuminated letters mounted on a foliage wall by Signs Base

Planning Permission for External Signs

For any external illuminated signage, planning permission is a mandatory requirement. This process can take anywhere from 8 to 10 weeks, depending on the local council’s regulations and workload. It’s important for clients to factor this timeline into their project planning to avoid delays. Assistance with the application process, including providing the necessary documentation, is often available to help ensure a smooth approval process.

By following these detailed steps, the installation of illuminated letters is not only visually stunning but also safe, secure, and compliant with all relevant regulations. Signs Base, with its commitment to quality and attention to detail, ensures that your signage will shine brightly for years to come.

For projects like these, it's always best to rely on a professional contractor to ensure everything is done correctly and safely. Signs Base specializes in illuminated signage, offering expert services from planning and installation to final testing, ensuring your sign not only looks fantastic but also meets all necessary regulations.